Polypropylene pipes.

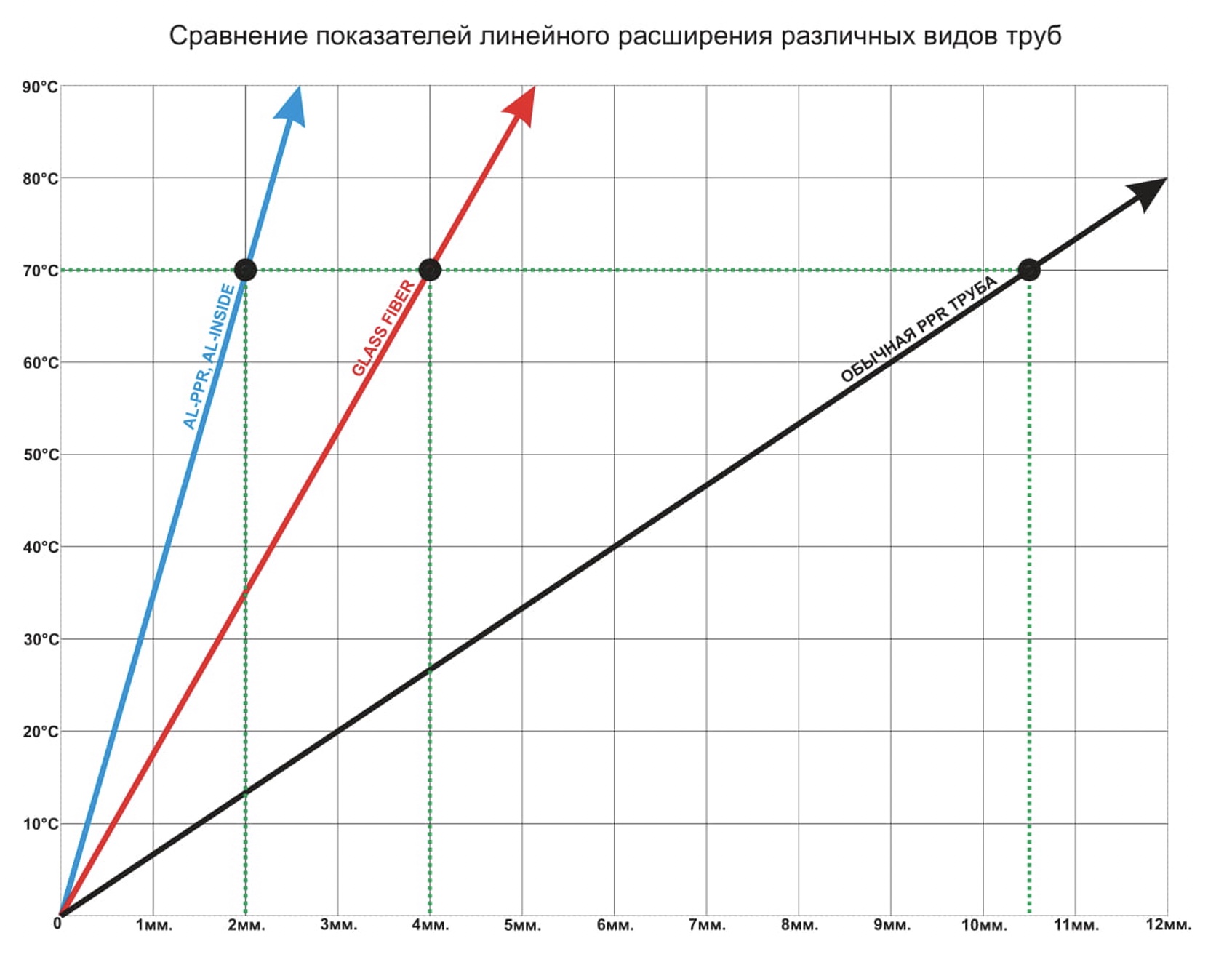

Installation of polypropylene pipes must be carried out at an ambient temperature of at least +5 ° C by a qualified specialist. Pipe connections must be made by thermal polyfusion socket welding using a special welding machine. Setting operating temperature 260 ° C. It is recommended to use fittings for socket welding of the same quality in terms of Melt Flow Index or follow the seller's recommendations. In this case, simultaneous heating to the working depth of the pipe and fitting is guaranteed. The heating time when making the connections must correspond to that stated in the technical characteristics. Pipes that have been stored or transported at temperatures below 0°C must be cured for 2 hours before installation at a temperature not lower than +5 ° C. Installation of systems made of reinforced polypropylene pipes should be carried out in accordance with the requirements of current regulatory documents. When installing, be sure to take into account the Linear Expansion Indicators of each type of polypropylene pipes. Comparative indicators of this parameter are shown in the graph.

IPEX pipes

Installation of pipes should be carried out at an ambient temperature of at least 10 ° C with a specially designed tool and a qualified specialist. It is recommended to use push-in fittings as pipe connectors. Flattening and fractures of the pipeline during installation are not allowed. In case of “kinking”, the damaged section of the pipe must be removed. It is allowed to warm up the broken section with a construction fan until it restores its original shape (shape memory effect). However, in this case, the design pressure of the working medium must be reduced by 20%. Coils of pipes that have been stored or transported at temperatures below 0 ° C must be kept for 8 hours at a temperature not lower than 10 ° C before rolling. When bending a pipe with a radius close to the limiting one (5 OD), it is recommended to preheat the pipe to a temperature of 130 ° C with a construction fan. In order to avoid straightening of the bent pipe section during heating (memory effect), at the points of bending, the pipes should be fastened with clamps or brackets with a step of 10 cm. The underfloor heating pipeline should be filled with concrete or covered with a coating only after hydraulic tightness tests. Recommended test schedule: 5-6 hours with a water temperature of 70-80°C and a pressure of 0.3 MPa. When pouring, the pipe must be under a pressure of 0.3 MPa. The minimum height of the grout over the pipe surface must be at least 3 cm. Mechanical damage to the EVOH layer increases the oxygen permeability of the pipeline. After installation, the system must be subjected to a hydraulic test with a static pressure of 1.5 times the operating pressure, but not less than 6 bar. The hydraulic test is carried out in accordance with the procedure described in SP73.13330.2016.

PE-RT pipes

Installation of pipes should be carried out at an ambient temperature of at least 5°C with a specially designed tool and a qualified specialist. It is recommended to use press fittings as pipe connectors. Crimp connectors can be used for “cone” and “eurocone” connections. Flattening and fractures of the pipeline during installation are not allowed. In case of “kinking”, the damaged section of the pipe must be removed. Coils of pipes that have been stored or transported at temperatures below 0°C must be kept for 24 hours at a temperature not lower than 10°C before rolling. The free pipe ends must be closed with plugs to prevent dirt and debris from getting inside the pipe. When bending a pipe with a radius close to the limiting one (5 OD), it is recommended to preheat the pipe to a temperature of 120°C with a construction fan. In places where pipes are turned, they should be fastened with clamps or brackets with a pitch of 15 cm. The underfloor heating pipeline should be filled with concrete or covered with a coating only after hydraulic tightness tests. When pouring, the pipe must be under a pressure of 0.3 MPa. Hydraulic tests are carried out in accordance with the instructions of SP 73.13330.2016. The minimum height of the grout over the pipe surface must be at least 3 cm. The pipe must be protected from direct sunlight.